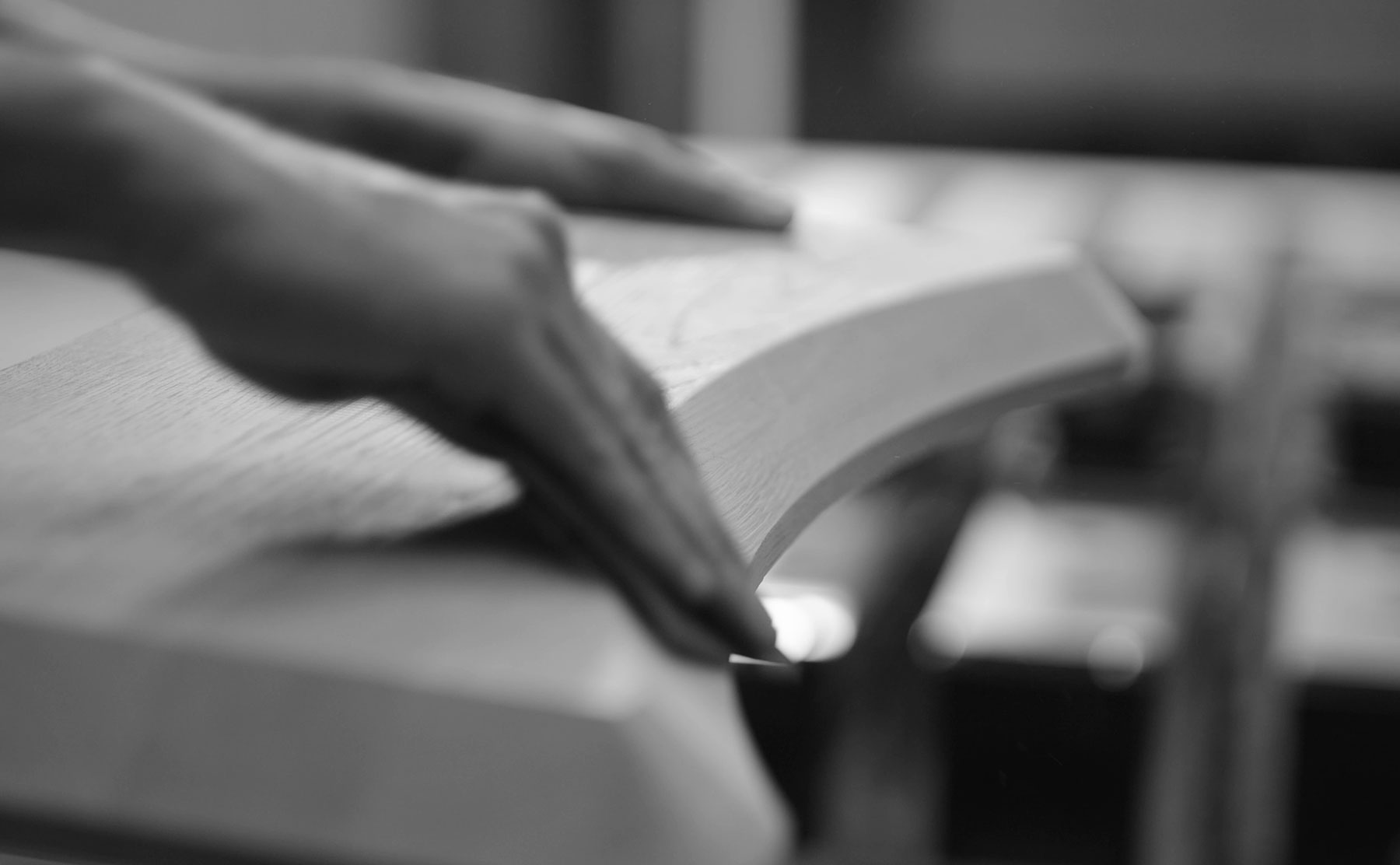

Our painters are constantly searching for exactly the wood finish they want. Depending on the type of wood, they may choose to treat the surface first by brushing it with hard steel or soft brass to remove the soft part of the wood and reveal a deeper grain. Bleaching, staining or applying an antique finish changes the colour of the wood while leaving the character of the wood intact. Oak and zebrano are often treated in this way. Walnut, however, has its own characteristic colour.

Vonder is specialised in exclusive metal finishes for wood, such as the bronze finish. The surface is preserved by applying varnish, oil or a wax finish. Spraying is done in a special dust-free cubicle. The finish can be transparent or opaque, and matt, silk or high-gloss. The wood can also be French polished, with varnish being applied in overlapping layers which are then sanded down finely until the grain is completely filled and the surface gleams. Varnish can also be applied using a brush. The best quality is achieved at our own workshop in Enter, but in some cases our furniture can be finished at its final destination, even after assembly.

Oak and wenge are generally brushed to show off the grain better, after which colour is added to achieve the right shade and look. Walnut, however, has a characteristic colour of its own.

We use a water-based primer in our spraying department. The high-quality, certified varnishes we use at Vonder were originally developed for shipbuilding. They contain no heavy materials and are of the very best quality: fire retardant, colour-fast, resistant to chemicals, and water and scratch-proof (IMO.MSC. 61 Fire-retardant Din 4102 (R1) Chemical resistance, 1HO Din 68861, TUV Toxproof). This quality cannot be achieved with water-based varnishes, although testing is continuing. The spray mist emitted by the high solid varnishes is collected in filters, making it less damaging for the environment.